How Do Test Weights Ensure Accurate Measurements?

- amol shinde

- Jun 25, 2025

- 3 min read

Updated: Jan 4

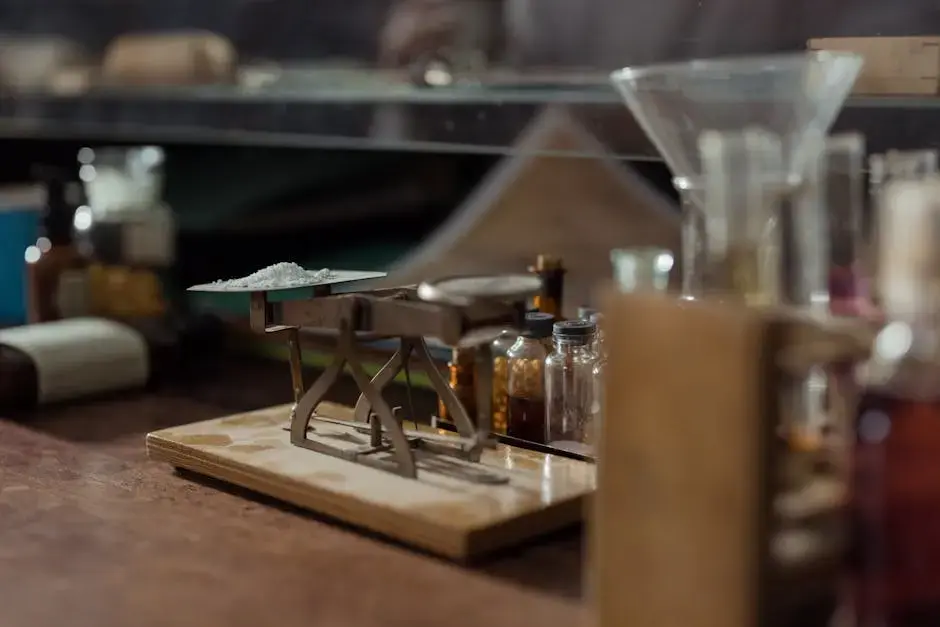

In the world of precise measurements, every detail matters. Understanding how test weights work is key to ensuring accuracy whether you're calibrating scales in a laboratory or checking the weight of ingredients in a kitchen. But how do these seemingly simple objects contribute to precise measurements? In this FAQ, we’ll break down everything you need to know about test weights and their essential role in various fields.

What Are Test Weights?

Test weights are standardized weights used to calibrate and verify the accuracy of scales and balances. They come in various classes and denominations based on international standards, ensuring measurements are as precise as possible.

The precision of test weights is critical in numerous fields. From pharmaceutical labs to culinary kitchens, these weights assure that scales provide the exact measurement needed for accuracy in their respective industries.

These weights play an essential role by acting as a benchmark against which the scale can be compared, ensuring that the measurement results remain consistent and within required standards.

Why Is Calibration Important?

Calibration is the process of configuring an instrument to provide results within an acceptable range. It's crucial because even the most advanced scales can drift or show errors over time without regular checks using test weights.

By regularly calibrating your scales, you prevent potential inaccuracies which can lead to errors in research outcomes, production processes, or any measurements crucial to project success.

Routine calibration ensures that slight deviations, which may occur due to wear and tear, temperature fluctuations, or gravitational changes, are corrected to maintain measurement integrity.

Types of Test Weights You Need to Know

Different applications require different types of test weights. From precision weights used in laboratories to heavy-duty industrial weights, understanding the right type for your needs ensures optimal accuracy.

Precision weights are often used in laboratories where even the slightest measurement error can have significant consequences. Conversely, heavy-duty industrial weights are designed for environments where bulk material weighing is common.

Material choice for test weights is also vital. Stainless steel, cast iron, and high-density materials are commonly used depending on the intended application and environmental conditions learn more about the materials here.

How to Use Test Weights Correctly

Using test weights properly involves more than just placing them on a scale. Proper handling, avoiding contamination, and following manufacturer instructions are key to obtaining accurate results.

Before using test weights, ensure that both the weights and the scales are clean. Dust or foreign particles can significantly affect the accuracy of the measurement.

Always handle Class 1 test weights with gloves to prevent dirt and oils from your skin from compromising the surface of the weight, which can lead to inaccurate calibration results.

Maintaining and Storing Calibration Test Weights

To extend their lifespan and ensure continued accuracy, test weights need to be maintained and stored appropriately. This includes regular cleaning, avoiding exposure to extreme conditions, and proper handling.

Test weights should be stored in dedicated cases to protect them from environmental factors that may alter their mass, such as humidity and dust accumulation.

Regular audits of test weights ensure they remain within their tolerance levels, which is necessary for maintaining the precision of measurements consistently over time.

Ensuring Traceability with Test Weights

Traceability in test weights means the ability to verify their conformity to standards through an unbroken chain to a national or international standard. This is crucial for ensuring the weights' validity in high-stakes measurements.

When calibration test weights are traceable, it enhances their credibility in scientific and industrial applications by providing assurance that they meet specified regulations and quality standards.

A well-documented traceability system allows one to track when and how frequently weights are used and calibrated, providing accountability and reliability in any measurement system.

The Importance of Test Weights in Achieving Measurement Accuracy

Accurate measurements are the foundation of successful experimentation and quality assurance, and test weights are pivotal in achieving this precision. By understanding the types, maintenance, usage, and traceability of test weights, one can ensure that measurements remain consistent and reliable across different applications. Mastering the use of calibration test weights safeguards against potential inaccuracies, ultimately highlighting their indispensable role in both scientific and everyday scenarios. To explore further how test weights can benefit your operations, visit American Scale Supply today.

Comments